Press

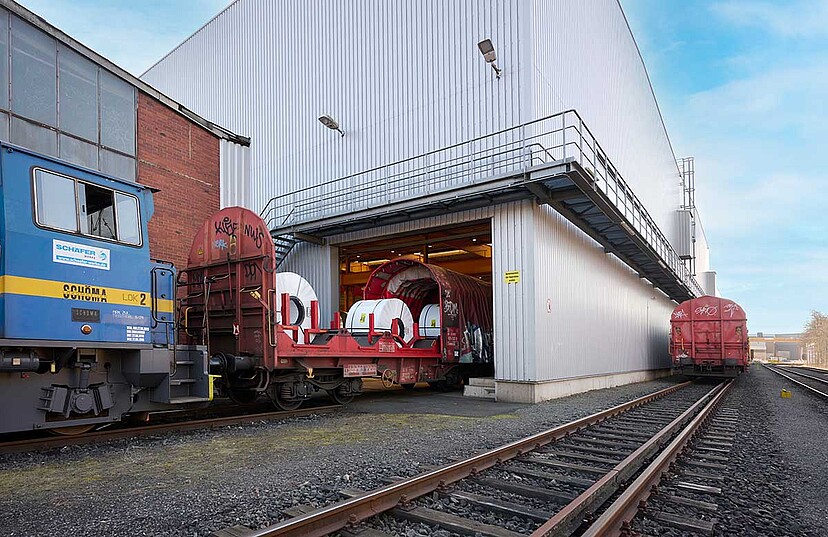

Neunkirchen, 6th March 2023. With the aim of concentrating locations, EMW Stahl Service GmbH, a business unit of the SCHÄFER WERKE Group headquartered in Neunkirchen, has acquired the northern part of the former EEW Bergrohr production site in Siegen-Weidenau. The property comprises around 23,000 square metres of commercial space, production halls and its own rail connection.

A warehouse with a capacity of 100,000 tonnes of steel sheet is being built on the former production site, with the possibility to extend it in future. The factory halls are equipped with state-of-the-art technology, including new crane systems for four handling areas, as well as a sophisticated loading and safety concept. Total investments in the double-digit million range were made.

Due to constant growth over the past few years, new external warehouses have been built at various locations – a logistical challenge in terms of the availability and transport of goods. By concentrating the numerous external warehouses that were previously required at this new central location, it was possible to reduce their number from thirteen to three.

The concentration of locations brings many advantages due to the significant shift of goods transport to more environmentally friendly rail transport and reduces the demand for long-distance road traffic – a clear benefit for the region and the environment.

"The long-standing successful cooperation with Kreisbahn Siegen-Wittgenstein and Deutsche Bahn has also proven its worth in this project and is leading to a significant shift in logistics – away from the roads and towards more environmentally friendly rail transport. We have therefore achieved our goal of concentrating locations on our way to becoming significantly more sustainable," says Michael Mockenhaupt, Chairman of the Management Board at EMW Stahl Service GmbH.

A good half of the truck journeys that were necessary up to now will be eliminated. Thanks to the extensive railway siding on the site in Weidenau, the production facility at the main Pfannenberg site in Neunkirchen, about 25 kilometres away, can be supplied just in time by goods train from there. Coils are delivered to be further processed into slit strips, perforated sheets and round blanks. In the future, at least two thirds of incoming goods will be received by rail. 300,000 tonnes of steel per year are already being transferred from road to rail – the aim for the future is 600,000 tonnes. This is an impressive figure, because in return 13,000 truck journeys are saved. Optimising the logistics processes will lessen the impact of heavy goods traffic on the entire region.

"Anyone who transports their goods by rail is taking an important step in reducing their carbon footprint. A goods train cuts carbon dioxide emissions by more than 80 per cent compared to road transport. This makes rail the most sustainable mode of transport. We were happy to support EMW in its plan to jointly shift even more freight to environmentally friendly rail transport and to reduce congestion on the roads," explains Kai Maaß, Head of Regional Sales for Germany at DB Cargo.

Both DB Cargo AG and Kreisbahn Siegen-Wittgenstein have developed a production concept for inbound and outbound transport for the Weidenau site. Incoming wagons are unloaded and reloaded on the same day. Delivery to the production site in Neunkirchen/Pfannenberg takes place on the same day.

"Over the last two decades, we have been able to increase the rail-side transport volume tenfold via our railway infrastructure which was built by the Freien Grunder Eisenbahn to the Pfannenberg site. We are extremely pleased to now be able to start the next chapter of our cooperation together and also welcome EMW with a siding on the Weidenau-Deuz light railway," states Christian Betchen, Managing Director of KSW Kreisbahn Siegen-Wittgenstein GmbH.

The EMW Steel Service Centre recently received the silver EcoVadis certificate for its sustainability performance. EcoVadis has become the world's largest and most trusted provider of corporate sustainability ratings, having built up an international network of more than 100,000 rated companies.

As a family-owned company, the SCHÄFER WERKE Group has embodied expertise and innovation in steel processing with over one thousand employees in diversified business units since 1937. With two locations, the EMW business unit is one of the largest mill-independent steel service centres in Europe.